quotes and solutions

+8619870423316

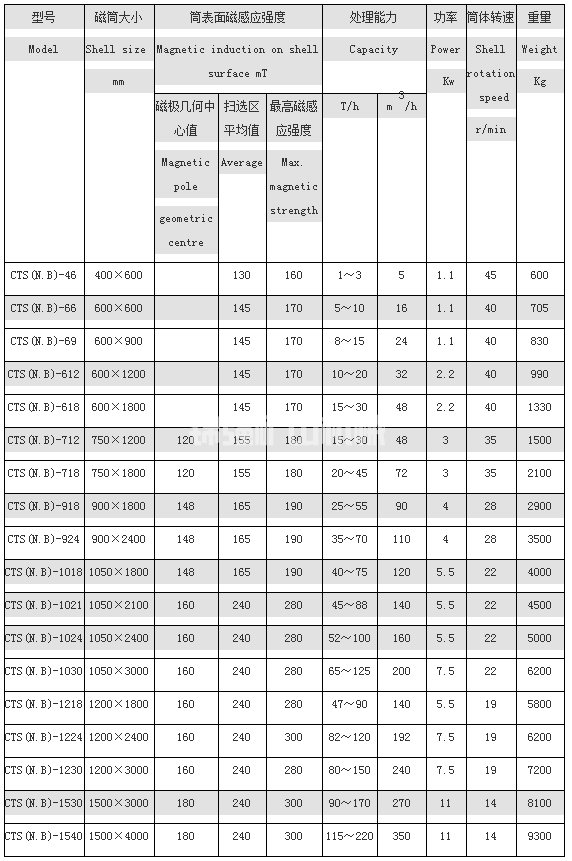

productivity:10-280t/h

Processing materials:Magnetite, pyrrhotite, calcined ore, ilmenite, coal, non-metallic ore, etc. below 3mm

Application scope:0-3mm

Feed particle size:0-3mm

Equipment processing capacity:10-280t/h

Production materials:Magnetite, pyrrhotite, calcined ore, ilmenite, coal, non-metallic ore, etc. below 3mm

1、 Introduction

The drum magnetic separator is an equipment designed according to the mineral characteristics of Hematite and the characteristics of the concentrator. The prominent feature of the structure type is that the magnetic system is wrapped with a drum outside to maintain the internal magnetic system or the drum and magnetic system are rotated relatively to complete good removal of non-magnetic minerals mixed in the copper mine. The strong magnetic drum magnetic separator is used for the work of Hematite concentrator. According to the different working natural environment of the concentrator, the strong magnetic drum magnetic separator with different structure can be used to carry out the work of wet magnetic test separation equipment, dry magnetic test separation equipment, rough separation, optimization and scavenging, as well as block magnetic separation equipment and fine sand magnetic separation equipment.

2、 Principle

The permanent magnet drum type magnetic separator is based on the magnetic difference between raw materials, and the magnetic and mechanical forces acting on various particles are different, resulting in different trajectories and thus completing the screening work. Place the raw materials into the magnetic separator, where the magnetic particles are magnetized without the uniform electromagnetic field effect. When attracted by the electromagnetic field, the magnetic particles will move along the direction of increased magnetization until they are absorbed on the drum or continuous recycling machine, and then discharged along with the fitness exercise of the conveyor belt. Those without magnetism will still be left in the waste and discharged.

3、 Structure

The strong magnetic drum magnetic separator equipment is composed of left and right shells, rare earth permanent magnet drums, motors, etc. Raw materials are fed into the magnetic drum from the hopper. According to the uniform distribution of the fabric separator, there are two feeding ports at the lower side of the shell. One is the feeding port of magnetic raw materials, and the other is the feeding port of non-magnetic raw materials. During the whole operation process of the strong magnetic drum magnetic separator, the composition of Magnetochemistry substances in the raw materials can be manipulated according to the adjustment spindle, and the rare earth permanent magnetic system structure is selected for sustainable operation, Having the characteristics of saving resources and being trustworthy.

4、 Advantages and characteristics

1. Overall design effective

It is composed of a shell, 2 magnetic core equipment, 2 slag cleaning equipment and transmission system. Several high toughness electromagnets are assembled into a drum that produces a magnetic induction line of mesh structure on the surface. The slag cleaning equipment and drum form a magnetic Closed system to produce an effective design scheme.

2. Magnetic source selection of rare earth permanent magnet materials with excellent performance

The permanent magnet drum type magnetic separator uses high-performance rare earth permanent magnet materials as the magnetic source. In terms of work, the selected raw materials are separated in the electromagnetic field on the surface of the drum, relying on the effectiveness of magnetic and mechanical equipment forces on particles. The advantages of using strong magnetic separation equipment and cationic reverse flotation agents further improve the efficiency of the magnetic separation equipment and enhance customer production and manufacturing profits.

3. High precision ore dressing plant

The permanent magnet drum type magnetic separator is used in mineral processing plants for scientific research on its principles, which is beneficial for the purification of minerals, the improvement of grade, and the next step in the production and processing of silicon powder raw materials. It has high screening accuracy and can reasonably generate significant profits for customers, making it highly worthy of marketing and promotion.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316