quotes and solutions

+8619870423316

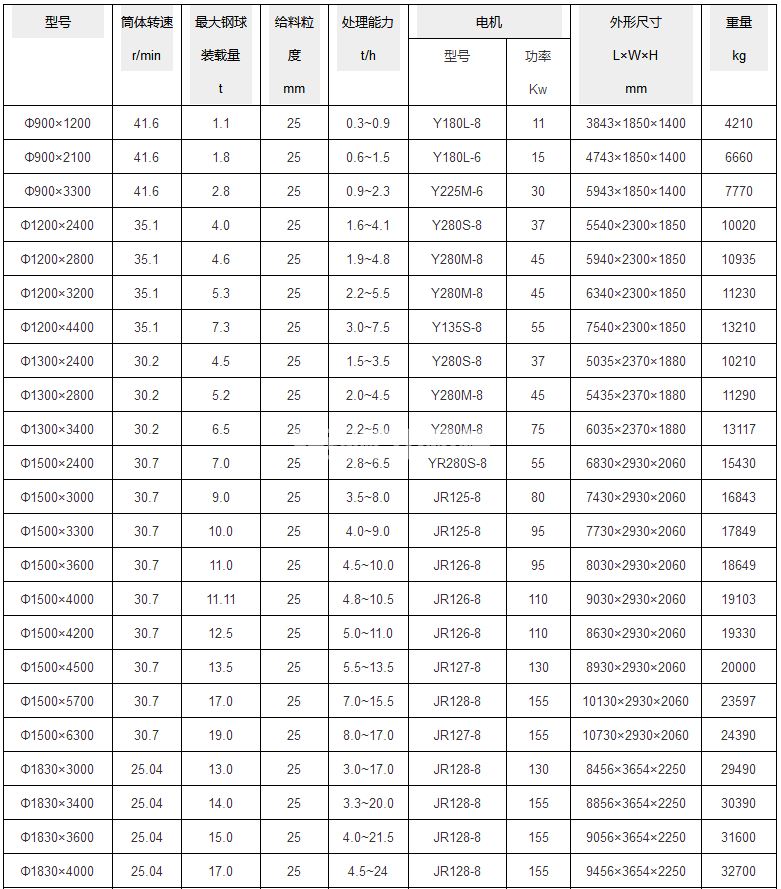

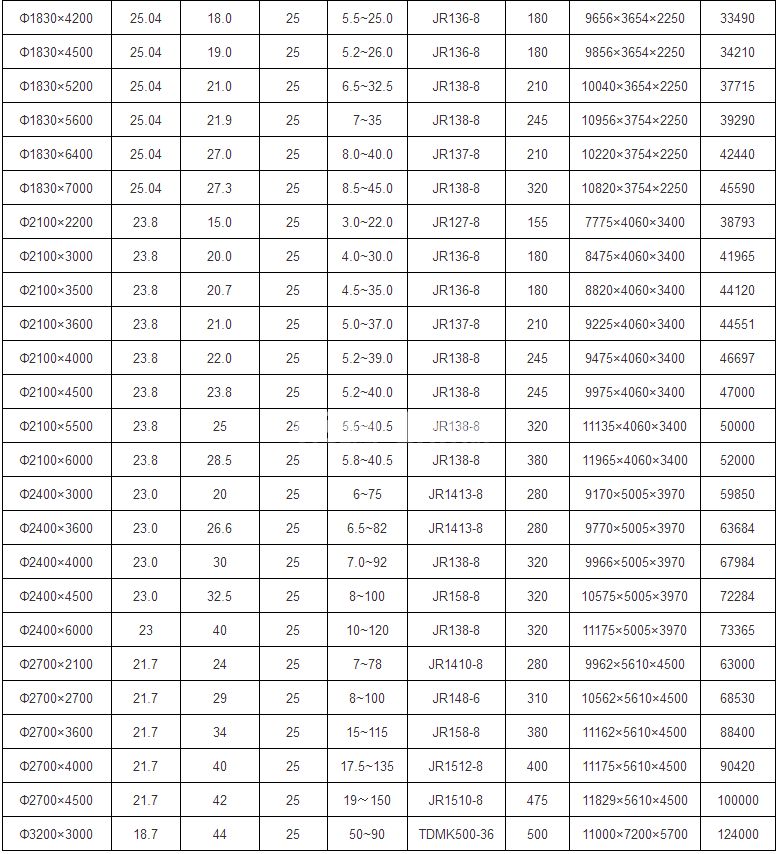

productivity:0.65-615t/h

Processing materials:Mineral processing of cement, new building materials, silicates, refractory materials, fertilizers, ferrous metals, and non-ferrous metals, glass ceramics, etc

Application scope:≤25mm

Feed particle size:≤25mm

Equipment processing capacity:0.65-615t/h

Production materials:Mineral processing of cement, new building materials, silicates, refractory materials, fertilizers, ferrous metals, and non-ferrous metals, glass ceramics, etc

1、 Introduction

The beneficiation ball mill equipment is a key machine and equipment for mining and beneficiation, which can separate and select different mineral materials from minerals, and separate them into tailings ponds. It is particularly important to improve the quality of selected ore materials. It can produce and process various types of grinding materials, rare metal beneficiation, and new building decoration materials. The selected ore has uniform particle size and excellent quality.

2、 Advantages and characteristics

Mine ball mills with different diameters, specifications, models, and types can be provided to various metallurgical industries, chemical plants, and mining companies.

Replacing rolling bearings with roller bearings can save more than 30% electricity;

The mandatory ore discharge equipment has been improved at the feeding end, resulting in a 40% increase in work capacity;

Automatic welding machine, Ultrasonic testing, overall quenching, large and medium-sized professional CNC lathes are selected for ball mill barrel joint, ensuring precision and quality;

The ball mill uses rare earth raw materials and a new type of construction jaw, adjusts the speed ratio of the ball mill, improves the sprocket design, and thus improves the stability and service life of the ball mill operation;

The entire mechanical installation and adjustment of the ball mill are carried out before leaving the factory, making on-site installation and operation convenient and convenient.

3、 Installation and Maintenance

The maintenance and upkeep of machines is an extremely important and frequent task, which should be closely coordinated with extreme operations and maintenance, and should be inspected by dedicated personnel on duty. The maintenance of a ball mill is a regular task, and the quality of the maintenance work directly affects the operating rate and service life of the ball mill. In order to timely detect defects and eliminate hidden dangers to ensure the normal operation of the mill, in addition to daily maintenance, it is also necessary to regularly stop grinding. (It is recommended to check important components such as hollow shafts, main bearings, cylinders, reducers, large and small gears, and make detailed records.). According to the severity of defects, appropriate handling and arrangement of intermediate and major repair plans should be made.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316