quotes and solutions

+8619870423316

Incineration slag refers to the solid residue produced in the process of Incineration, which usually contains a certain amount of metal components. If these metal components are not recycled, they not only waste resources but also cause pollution to the environment. Therefore, metal recovery from Incineration slag has become an important field in the current environmental protection industry.

I. Composition of Incineration slag

I. Composition of Incineration slag

The composition of Incineration slag mainly includes inorganic substances, organic substances and moisture. Inorganic substances include iron oxide, aluminum oxide, Calcium oxide, magnesium oxide, etc., while organic substances include alkanes, Aromatic hydrocarbon, etc. In addition, Incineration slag also contains a certain amount of metal components, such as copper, aluminum, zinc, iron, etc.

2、 Methods of recovering metal from Incineration slag

1. Magnetic separation method

1. Magnetic separation method

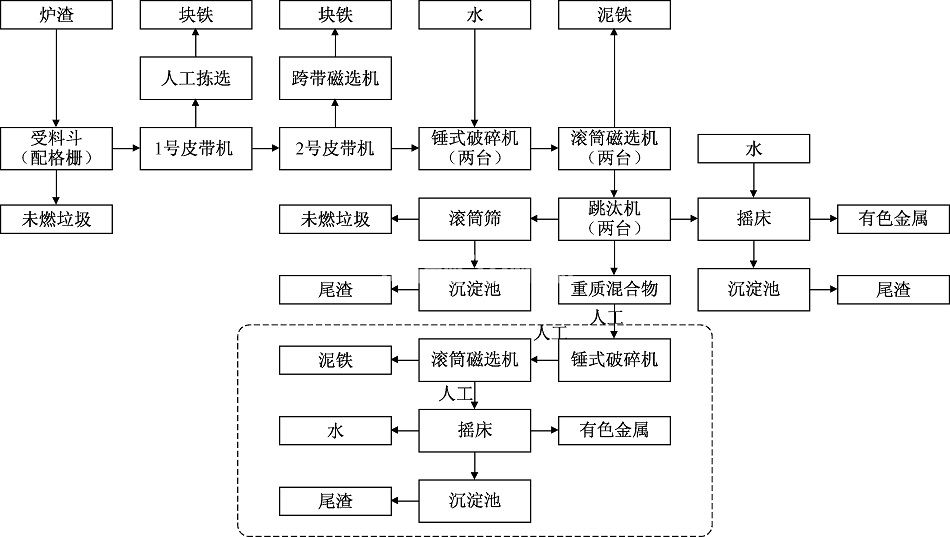

magnetic separation is a commonly used method to recover metal from Incineration slag. This method utilizes magnetic materials to separate metals, typically using equipment such as high-strength permanent magnets and electromagnets for magnetic separation. During the magnetic separation process, metals are adsorbed on magnetic materials, thereby achieving metal recovery.

magnetic separation is a commonly used method to recover metal from Incineration slag. This method utilizes magnetic materials to separate metals, typically using equipment such as high-strength permanent magnets and electromagnets for magnetic separation. During the magnetic separation process, metals are adsorbed on magnetic materials, thereby achieving metal recovery.

2. Gravity selection method

Gravity separation method is a method of separating metals by gravity. This method mainly uses the density difference between metals and nonmetals for separation, and usually uses centrifuges and other equipment for gravity separation. In the process of gravity separation, metals will settle to the bottom, while non-metals will float on the upper layer, thus achieving metal recovery.

3. Flotation method

Flotation method is a method of floating metals up through bubbles. This method mainly utilizes the difference in surface properties between metals and non-metals for separation, usually using flotation machines and other equipment for flotation. During the flotation process, bubbles will float the metal, thereby achieving metal recovery.

3、 Application of Metal Recovery from Incineration Slag

Metal recovery from Incineration slag is widely used, mainly including the following aspects:

1. Metallurgical industry

The metal composition contained in the Incineration slag can be used in steelmaking, casting and other processes in the metallurgical industry. By recycling these metals, not only can resources be saved, but also environmental pollution can be reduced.

2. Construction industry

The inorganic substances in Incineration slag can be used in the production of concrete, cement and other materials in the construction industry. These materials have high strength and durability, which can effectively improve the quality and lifespan of buildings.

3. Environmental protection industry

Metal recovery from Incineration slag can effectively reduce environmental pollution and waste discharge. This is of great significance for the development of the current environmental protection industry.

4、 Conclusion

Metal recovery from Incineration slag is an important field in the current environmental protection industry. Through the use of magnetic separation, gravity separation, flotation and other methods, the metal components in Incineration slag can be effectively recycled, thus saving resources and reducing environmental pollution. In the future, metal recovery from Incineration slag will be more widely used and developed.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316