quotes and solutions

+8619870423316

Perovskite is an important mineral resource widely used in fields such as architecture, ceramics, and electronics. However, the beneficiation process of perovskite is relatively complex and requires multiple steps to obtain high-purity products. This article will introduce the operating steps and related precautions of perovskite beneficiation experiments.

1、 Preparation before testing

1. Sample preparation

Firstly, it is necessary to prepare a sample of perovskite, which should be representative and undergo grinding, screening, and other processing to facilitate subsequent experimental operations.

2. Preparation of testing equipment

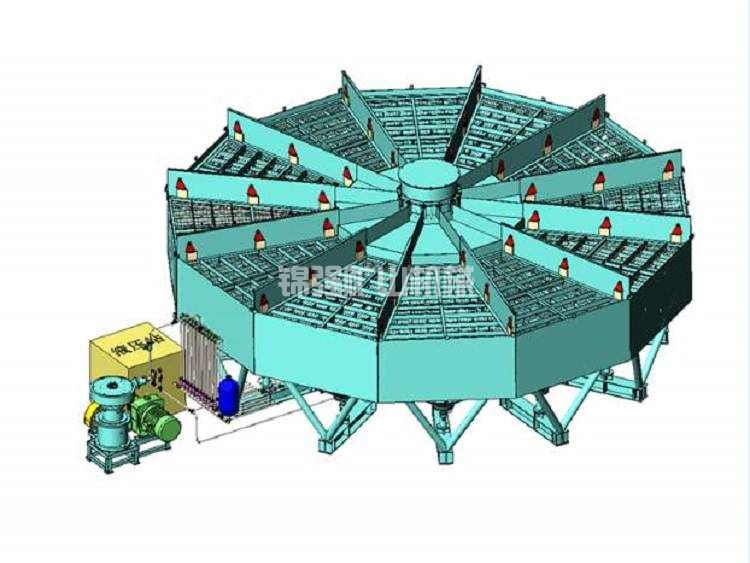

The perovskite beneficiation test requires the use of various equipment, such as magnetic separators, heavy medium beneficiation machines, flotation machines, etc. The corresponding equipment needs to be prepared in advance, and tested and maintained to ensure the normal operation of the equipment.

3. Preparation of experimental conditions

3. Preparation of experimental conditions

The beneficiation test of perovskite needs to be carried out under specific experimental conditions, such as temperature, humidity, atmosphere, etc. The experimental conditions need to be determined in advance and adjusted and controlled accordingly.

2、 Test steps

1. Magnetic separation

Perovskite often contains a certain amount of magnetic minerals, such as Magnetite and Hematite, which can be removed by magnetic separation. The operating steps for magnetic separation are as follows:

(1) Place the sample in the magnetic separator and turn on the magnetic separator.

(2) According to the magnetic strength of magnetic minerals, adjust the magnetic field strength and magnetic pole spacing of the magnetic separator to facilitate the separation of magnetic minerals.

(3) Collect the separated magnetic and non magnetic minerals for subsequent processing.

(3) Collect the separated magnetic and non magnetic minerals for subsequent processing.

2. Heavy medium beneficiation

Perovskite often contains minerals with high density, such as Apatite and Galena, which can be removed by heavy medium beneficiation. The operating steps for heavy medium beneficiation are as follows:

(1) Place the sample in a heavy medium concentrator and add the heavy medium liquid.

(2) According to the density difference of minerals, adjust the density of heavy medium liquid to facilitate the separation of minerals with higher density.

(3) Collect the separated minerals and non minerals for subsequent processing.

3. Flotation

Perovskite often contains a certain amount of Silicate mineral, such as quartz, feldspar, etc., which can be removed by flotation. The operation steps of flotation are as follows:

(1) Place the sample in the flotation machine, add the flotation agent and bubble generator.

(2) According to the hydrophilicity and hydrophobicity of minerals, adjust the type and amount of flotation agent to facilitate the separation of Silicate mineral.

(3) Collect separated Silicate mineral and non Silicate mineral for subsequent treatment.

3、 Precautions

During the experiment, it is necessary to pay attention to safety, such as wearing protective glasses, gloves, etc.

2. Before the experiment, it is necessary to inspect and maintain the equipment to ensure its normal operation.

3. The experimental conditions need to be strictly controlled to avoid affecting the experimental results.

4. The sample processing needs to strictly follow the prescribed procedures to ensure the accuracy and reliability of the experimental results.

Summary:

The perovskite beneficiation experiment is a complex experimental work that requires multiple steps of operation to obtain high-purity products. During the experimental process, attention should be paid to safety, equipment maintenance, and control of experimental conditions to ensure the accuracy and reliability of the experimental results.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316