quotes and solutions

+8619870423316

With the continuous acceleration of urbanization, garbage disposal has become an important task in urban management. Garbage power plants are a common method of garbage disposal, which can convert garbage into electricity and also generate a large amount of slag. Slag refers to the solid waste generated during the garbage power generation process, and its treatment is of great significance for environmental protection and resource utilization. This article will introduce the methods and steps of slag treatment in garbage power plants.

1、 Classification of slag

The slag generated by the  garbage power plant is mainly divided into two types: fly ash and bottom slag. Fly ash refers to the small particles that are drawn into the flue gas during the combustion process, while bottom slag refers to the solid substances remaining at the bottom of the furnace after combustion. The treatment methods for these two types of slag are different.

garbage power plant is mainly divided into two types: fly ash and bottom slag. Fly ash refers to the small particles that are drawn into the flue gas during the combustion process, while bottom slag refers to the solid substances remaining at the bottom of the furnace after combustion. The treatment methods for these two types of slag are different.

2、 Handling of fly ash

Fly ash is a small solid particle that is easily dispersed in the air and causes pollution to the environment. Therefore, the treatment of fly ash is very important. At present, there are several main methods for handling fly ash:

1. Electrostatic dust removal method

The  electrostatic precipitator method is a method of separating fly ash through the action of an electric field. Pass the flue gas through the electrostatic precipitator, use the positive and negative polarity of the electrode to adsorb the fly ash, make it adhere to the electrode, and then clean the electrode. This method can efficiently remove fly ash, but it requires a large amount of electrical energy consumption.

electrostatic precipitator method is a method of separating fly ash through the action of an electric field. Pass the flue gas through the electrostatic precipitator, use the positive and negative polarity of the electrode to adsorb the fly ash, make it adhere to the electrode, and then clean the electrode. This method can efficiently remove fly ash, but it requires a large amount of electrical energy consumption.

2. Mechanical filtration method

Mechanical filtration method is a method of filtering fly ash using a filter screen. Pass the flue gas through the filter screen, intercept the fly ash inside, and then clean the filter screen. This method does not require electricity consumption, but requires frequent replacement of the filter screen.

3. Chemical curing method

The chemical solidification method is to solidify fly ash into a solid substance that is not easily dispersed through chemical reactions. The flue gas is treated with a chemical curing agent to react with fly ash to form solid particles, which are then collected and treated. This method can effectively solidify fly ash, but requires a large amount of chemical curing agent.

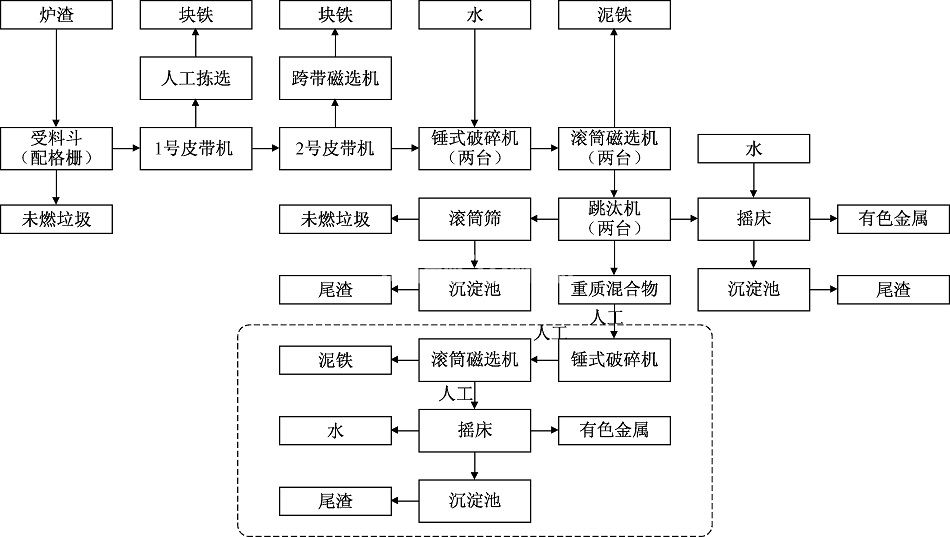

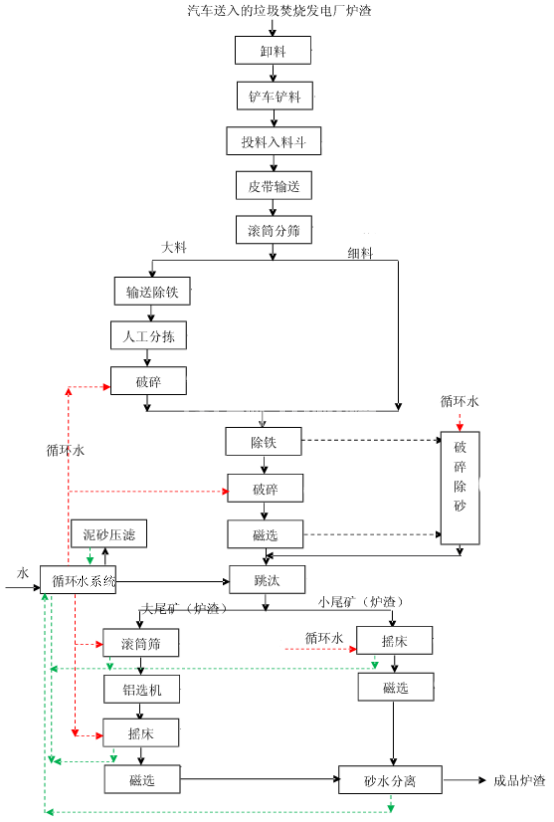

3、 Treatment of bottom slag

Bottom slag is a solid substance that needs to be classified and treated. The treatment methods for bottom slag mainly include the following:

1. Magnetic separation method

Magnetic separation method is a method of separating bottom slag through the action of a magnetic field. Pass the bottom slag through a magnetic separator, use magnetic force to separate the metal substances inside, and then recycle them. This method can efficiently recover metal substances, but it requires a large amount of electrical energy consumption.

2. Screening method

The screening method is a method of using a sieve to screen the bottom residue. Pass the bottom residue through a sieve to retain the large particulate matter, and then proceed with treatment. This method does not require electricity consumption, but requires frequent replacement of the screen.

3. Heat treatment method

3. Heat treatment method

The heat treatment method is a method of treating the bottom slag through high-temperature treatment. Send the bottom slag into a high-temperature furnace to decompose it into a substance that is easy to treat, and then collect and treat it. This method can effectively treat the bottom slag, but it requires a large amount of heat energy consumption.

4、 Summary

The slag treatment of garbage power plants is a very important task, which is related to environmental protection and resource utilization. The classification and treatment methods of slag are diverse and need to be selected based on actual situations. Electrostatic precipitation, mechanical filtration, and chemical solidification are the main methods for treating fly ash, while magnetic separation, screening, and heat treatment are the main methods for treating bottom slag. When carrying out slag treatment, it is necessary to pay attention to energy conservation, reduce pollution, and achieve maximum utilization of resources.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316