quotes and solutions

+8619870423316

Titanium ore sand is an important mineral resource widely used in fields such as aviation, aerospace, military, and medicine. However, the grade of titanium ore sand is relatively low, and it is necessary to improve the grade through gravity separation to meet the needs of industrial production. This article will introduce the gravity separation method of titanium ore sand, including the beneficiation process flow, operating steps, and precautions.

1、 Mineral processing process flow

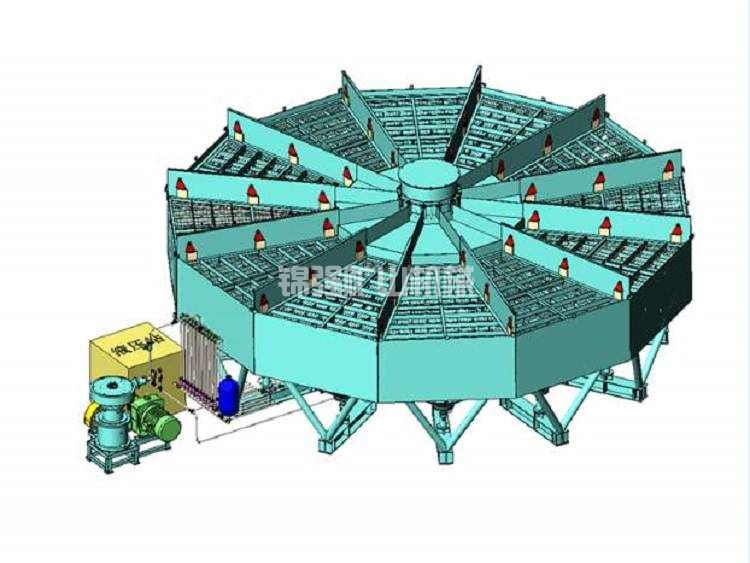

The general process flow of titanium ore gravity separation includes rough selection, intermediate selection, selection, and tailings treatment. Among them, rough selection mainly involves preliminary separation through a gravity separator to remove impurities from titanium ore sand and improve grade; The intermediate selection is carried out through a cyclone or spiral classifier for classification, and the coarse selected titanium ore sand is further separated; Selection involves fine separation through a gravity separator to improve grade; Tailings treatment is the treatment of remaining impurities to meet environmental requirements.

2、 Operating Steps

1. Rough selection stage

(1) Feed the titanium ore sand into the gravity separator for preliminary separation.

(2) According to the density difference of ore, adjust the vibration frequency and amplitude of the gravity separator to remove impurities.

(3) Send the separated titanium ore sand into the intermediate selection stage.

(3) Send the separated titanium ore sand into the intermediate selection stage.

2. Selection stage

(1) Classify the roughly selected titanium ore sand through a cyclone or spiral classifier.

(2) According to the density difference of ore, adjust the rotational speed and inclination angle of hydrocyclone or spiral classifier to separate titanium ore.

(3) Send the separated titanium ore sand into the selection stage.

3. Selection stage

(1) Feed the selected titanium ore sand into the gravity separator for fine separation.

(2) According to the density difference of ore, adjust the vibration frequency and amplitude of the gravity separator to further separate the titanium ore.

(3) Send the separated titanium ore sand into the tailings treatment stage.

4. Tailings treatment stage

(1) Dispose of the remaining impurities to meet environmental requirements.

(2) Discharge or recycle the treated tailings.

3、 Precautions

During the process of titanium ore gravity separation, attention should be paid to analyzing the properties of the ore in order to adjust the beneficiation process.

2. When adjusting the beneficiation process flow, it should be adjusted according to the density difference of ores, so as to improve the separation efficiency.

During tailings treatment, attention should be paid to environmental requirements in order to meet relevant national standards.

In summary, the gravity separation method of titanium ore is an important means to improve the grade of titanium ore. It is necessary to pay attention to the adjustment of the beneficiation process and the adherence to precautions in order to achieve the best separation effect and environmental protection requirements.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316