quotes and solutions

+8619870423316

Slag is an inevitable solid waste generated during the power generation process of power plants, mainly composed of impurities, ash, minerals, etc. in the fuel. If left untreated, slag can cause environmental pollution and affect people's lives and health. Therefore, professional slag treatment in power plants is very necessary.

1、 Classification of slag

The slag generated by power plants can be divided into two categories: ash and slag balls.

Ash refers to the ash generated during the combustion process, which is mainly composed of inorganic substances in coal powder and organic substances in coal. The particle size of ash varies, some are very fine and some are large, and the heavy metals and harmful substances contained in it can cause pollution to the environment.

slag ball refers to the molten substance generated during the combustion process, which is mainly composed of minerals in coal. The forms of slag balls are diverse, some are spherical, some are blocky, and the metal elements such as iron and aluminum contained in them can be recycled.

slag ball refers to the molten substance generated during the combustion process, which is mainly composed of minerals in coal. The forms of slag balls are diverse, some are spherical, some are blocky, and the metal elements such as iron and aluminum contained in them can be recycled.

2、 Treatment method of slag

1. Fly ash treatment

Fly ash is one of the main slag generated in power plants, which can be treated through both dry and wet methods.

Dry processing: Fly ash is transported to the storage bin through a conveyor belt, and then sent to a crusher for crushing through the conveyor belt. The crushed fly ash can be transported to the coal bunker for storage through conveyor belts, or to relevant enterprises such as cement plants for utilization.

Wet treatment: After mixing fly ash and water, it is stirred through a mixer to form a mud like substance, which is then separated by a centrifuge. The separated solid can be transported to the coal bunker for storage through a conveyor belt, or to relevant enterprises such as cement plants for utilization.

2. Slag ball treatment

2. Slag ball treatment

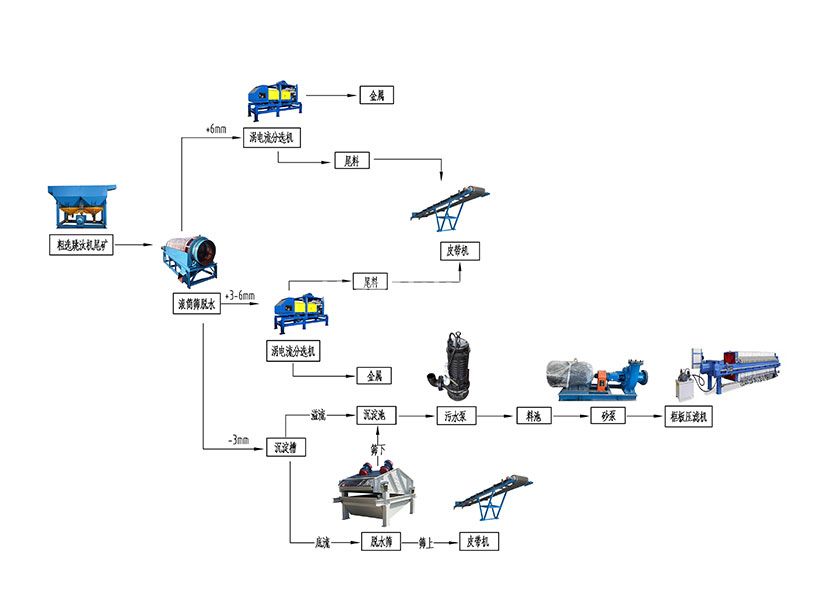

Slag balls are another major type of slag generated in power plants, which can be treated through two methods: magnetic separation and gravity separation.

magnetic separation treatment: The slag balls are transported through a conveyor belt to a magnetic separator for treatment. The magnetic separator separates the iron elements from them, and the separated iron elements can be recycled.

magnetic separation treatment: The slag balls are transported through a conveyor belt to a magnetic separator for treatment. The magnetic separator separates the iron elements from them, and the separated iron elements can be recycled.

Re-selection treatment: The slag balls are sent to the gravity separator through a conveyor belt for processing. The gravity separator separates the aluminum and other metal elements from them, and the separated metal elements can be recycled.

3、 The significance of professional power plant slag treatment

The significance of professional power plant slag treatment is to reduce the pollution of slag to the environment, and at the same time, it can also recycle useful elements, reducing production costs for enterprises. By treating slag, it can be turned into a useful resource, bringing more economic and environmental benefits to society and enterprises.

4、 Conclusion

The slag treatment of professional power plants is a very important link in the production process of power plants. It not only reduces the pollution of slag to the environment, but also recycles useful elements, bringing more economic and environmental benefits to society and enterprises. Therefore, power plants should attach importance to the treatment of slag and adopt scientific methods to contribute to the construction of a beautiful China.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316