quotes and solutions

+8619870423316

Sand titanium ore is a common type of titanium ore, mainly used in the production of titanium alloys, titanium dioxide and other products. Sand titanium beneficiation technology refers to a technology that processes sand titanium ore and extracts titanium metal from it. This article will introduce the operating steps and precautions of sand titanium beneficiation technology.

1、 Operation steps of sand titanium beneficiation technology

1. Crushing and grinding of sand titanium ore

First, it is necessary to crush and grind the placer titanium ore to reach the Granularity suitable for beneficiation. There are many methods for crushing and grinding, which can be selected according to actual situations.

2. Flotation of sand titanium ore

2. Flotation of sand titanium ore

After crushing and grinding, the sand titanium ore is placed in a flotation tank for flotation. Flotation refers to the use of physical or chemical methods to make mineral particles contact with bubbles, so that mineral particles and foam rise together to achieve mineral separation. During the flotation process, some reagents need to be added to improve the beneficiation efficiency.

3. Magnetic separation of sand titanium ore

After flotation, some magnetic minerals will still remain in the sand titanium ore. In order to remove these minerals, magnetic separation is required. Magnetic separation refers to a method of separating magnetic and non magnetic minerals by utilizing their different behaviors in a magnetic field.

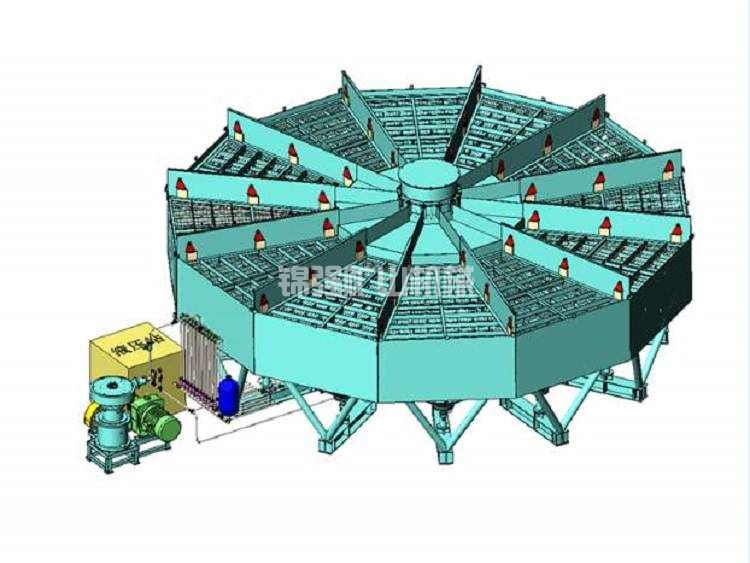

4. Gravity separation of sand titanium ore

After magnetic separation, some impurities will still remain in the sand titanium ore. To remove these impurities, re selection is necessary. Reselection refers to a method of separating minerals by utilizing their different behaviors at different densities.

5. Drying and packaging of sand titanium ore

After re selection, the purity of the sand titanium ore has reached a certain level. To further improve purity, it is necessary to dry it. After drying, packaging is carried out for easy storage and transportation.

Notes on sand titanium beneficiation technology

1. In the process of crushing and grinding, attention should be paid to controlling Granularity so as not to affect the subsequent beneficiation effect.

During the flotation process, attention should be paid to the type and dosage of reagents to achieve the best beneficiation effect.

During the magnetic separation process, attention should be paid to the strength and direction of the magnetic field to avoid affecting the separation effect.

During the re selection process, attention should be paid to density control to achieve the best separation effect.

During the drying and packaging process, attention should be paid to temperature and humidity control to avoid affecting the quality of minerals.

In summary, sand titanium beneficiation technology is a complex process that requires strict control of each link to ensure beneficiation efficiency and mineral quality. I hope this article is helpful to you.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316