quotes and solutions

+8619870423316

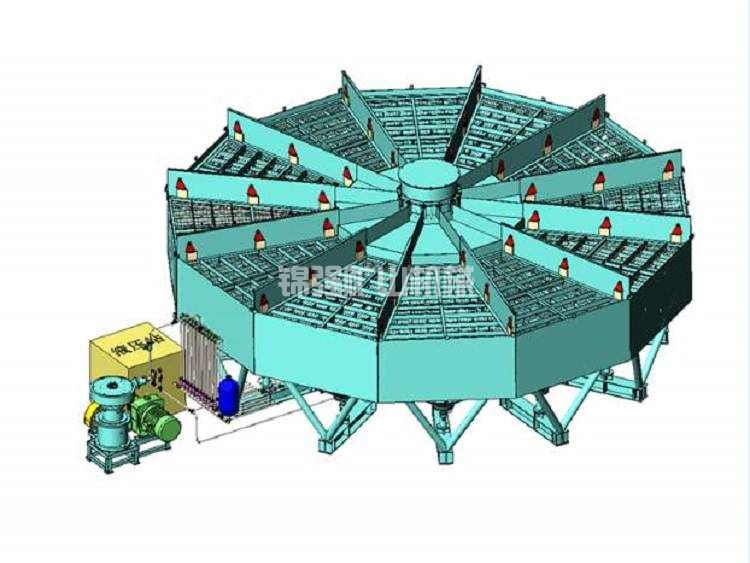

Sand zirconium ore is an important mineral resource, widely used in fields such as ceramics, refractory materials, chemical industry, electronics, etc. The production line for selecting sand zirconium ore is an important link in the processing of sand zirconium ore, which can effectively improve the quality and output of sand zirconium ore. This article will introduce how to choose a production line for sand zirconium ore and how to use it correctly.

1、 Selection and purchase of sand zirconium ore production line

1. Understand the characteristics and market demand of sand zirconium ore

Before purchasing a production line of sand zirconium ore, it is necessary to understand the characteristics and market demand of sand zirconium ore. Sand zircon ore generally contains substances such as zircon, quartz, phosphate, etc. The content and quality of these substances have a significant impact on the value of sand zircon ore. At the same time, it is necessary to understand the market demand for sand zirconium ore in order to select a production line suitable for the market demand.

2. Choose reliable suppliers

When choosing a production line for sand zirconium ore, it is necessary to choose reliable suppliers. Reliable suppliers can provide high-quality equipment and comprehensive after-sales service, ensuring the normal operation and maintenance of equipment.

3. Consider the applicable scope and production capacity of the production line

3. Consider the applicable scope and production capacity of the production line

When selecting a production line for sand zirconium ore, it is necessary to consider the applicable scope and production capacity of the production line. The scope of application includes the types and processing techniques of sand zirconium ore, and the production capacity is related to the scale of the production line and the performance of the equipment. It is necessary to choose a suitable production line based on actual production needs.

2、 Correct use of sand zirconium ore production line

1. Preparation before operation

Before using the sand zirconium ore production line, some preparation work needs to be done. First, check whether the equipment operates normally and whether there is abnormal sound and vibration. Secondly, it is necessary to check whether the electrical system and hydraulic system of the equipment are normal, whether there is leakage and oil leakage. Finally, it is necessary to check whether the power supply, water source and other facilities of the production line are normal.

2. Properly operate the sand zirconium ore production line

When operating the sand zirconium ore production line, it is necessary to follow the equipment manual for correct operation. It should be noted that the parameters and process flow of the equipment should not be changed arbitrarily to avoid affecting the normal operation of the equipment and the quality of the product. At the same time, it is necessary to pay attention to the safe operation of the equipment, such as wearing protective equipment and avoiding operational errors.

3. Regular maintenance and upkeep

3. Regular maintenance and upkeep

The sand zirconium mine production line is a large-scale equipment that requires regular maintenance and upkeep. Maintenance and upkeep include equipment cleaning, lubrication, and replacement of vulnerable parts. Regular maintenance and upkeep can extend the service life of equipment, improve its performance and stability.

III. Conclusion

The selection and correct use of sand zirconium ore production lines are important links to ensure the quality and output of sand zirconium ore processing. In the process of purchasing and using, it is necessary to pay attention to selecting reliable suppliers, considering the applicable scope and production capacity of the production line, conducting correct operations, and regular maintenance and upkeep. Only in this way can the quality and efficiency of sand zirconium ore processing be guaranteed, meeting market demand.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316