quotes and solutions

+8619870423316

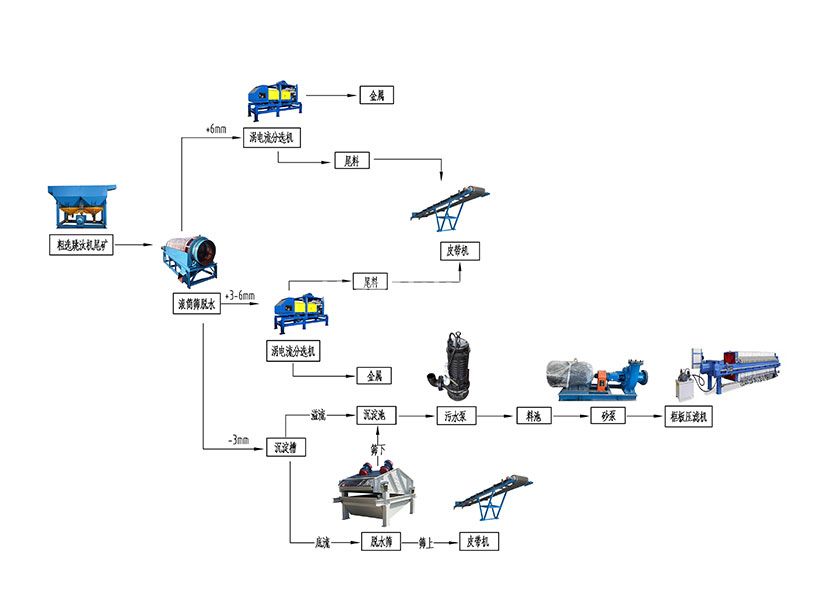

How to choose a suitable slag treatment equipment for power plants based on the price factors of the slag treatment equipment in this article? Conclusion: The operation steps of the power plant slag treatment equipment. The power plant slag treatment equipment is a type of equipment used to treat power plant slag, which is the solid waste generated by the combustion of coal, oil, natural gas and other fuels in the power plant. The power plant slag treatment equipment can separate, dry, crush, and magnetic separate the slag, making it a reusable resource and reducing environmental pollution.

There are many price factors for power plant slag treatment equipment, mainly including the following aspects.

Equipment model and specifications

The prices of different models and specifications of power plant slag treatment equipment may also vary. Generally speaking, the larger the specification of the equipment, the higher the price.

Manufacturer

The prices of slag treatment equipment in power plants vary among different manufacturers. Generally speaking, well-known brands have relatively high equipment prices, but their quality and after-sales service are also more guaranteed.

Market situation

The market situation is also one of the factors affecting the price of slag treatment equipment in power plants. If there is a high demand and insufficient supply in the market, equipment prices may rise. On the contrary, if there is sufficient supply and low demand in the market, equipment prices may decrease.

How to choose suitable slag treatment equipment for power plants? The selection of suitable slag treatment equipment for power plants requires consideration of the following aspects.

processing capacity

Processing capacity is one of the key factors in selecting slag treatment equipment for power plants. The processing capacity of the equipment needs to be selected based on the output and processing needs of the slag, to ensure that the equipment can meet production needs.

Processing effect

The treatment effect is also one of the important factors in selecting slag treatment equipment for power plants. The treatment effect of the equipment needs to be selected based on the properties and treatment requirements of the slag to ensure that the treated slag can meet the requirements of reuse.

Equipment quality and after-sales service

The quality of equipment and after-sales service are also important factors in selecting slag treatment equipment for power plants. We need to choose a reputable manufacturer to ensure the quality of equipment and after-sales service.

The operation steps of power plant slag treatment equipment mainly include the following aspects.

Separation of slag

Two methods can be used to separate slag from the flue gas of the power plant, wet or dry. Wet method refers to the treatment of flue gas through spray tower or cyclone separator, while dry method refers to the treatment of flue gas through Electrostatic precipitator or bag filter.

Drying of slag

Drying treatment of slag can be carried out using two methods: hot air drying or fluidized bed drying. Hot air drying refers to drying the slag through hot air, while fluidized bed drying refers to drying the slag through a fluidized bed.

Crushing and magnetic separation of slag

The dried slag can be crushed and magnetically separated using equipment such as ball mills and magnetic separators.

There are many price factors for slag treatment equipment in power plants, and it is necessary to choose suitable equipment based on one's own needs and budget. When selecting equipment, it is necessary to consider factors such as processing capacity, processing effectiveness, equipment quality, and after-sales service. When using the device, it is necessary to follow the operating steps to ensure the normal operation and processing effect of the device.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316