quotes and solutions

+8619870423316

Black tungsten is an important tungsten ore with a high tungsten content, but its beneficiation technology is relatively complex. This article will introduce the operational steps of black tungsten beneficiation technology to help readers better understand black tungsten beneficiation technology.

Overview of black tungsten beneficiation technology

Black tungsten beneficiation technology refers to the process of separating useful minerals from black tungsten ore. The black tungsten beneficiation technology mainly includes flotation, gravity separation, magnetic separation and other processes. Among them, flotation is to separate Pyrite, Molybdenite and other sulfide minerals from wolframite by flotation; Gravity concentration is to separate Scheelite, Wolframite and other oxidized minerals from wolframite by gravity concentration; Magnetic separation is the separation of magnetic minerals from black tungsten ore through magnetic separation.

2、 Operation steps of black tungsten beneficiation technology

1. Ore crushing

Crush the collected black tungsten ore to make its Granularity meet the requirements of the beneficiation process. Usually, equipment such as jaw crushers and cone crushers are used for crushing.

2. Ore grinding

The crushed wolframite is grinded to make its Granularity finer. Usually, equipment such as ball mills and rod mills are used for grinding treatment.

3. Flotation

Flotation treatment will be carried out on the black tungsten ore after grinding treatment. Flotation is a key process for separating sulfide minerals from black tungsten ore. Generally, reagents such as Chalcopyrite collector and copper oxide collector are used for flotation.

4. Reselection

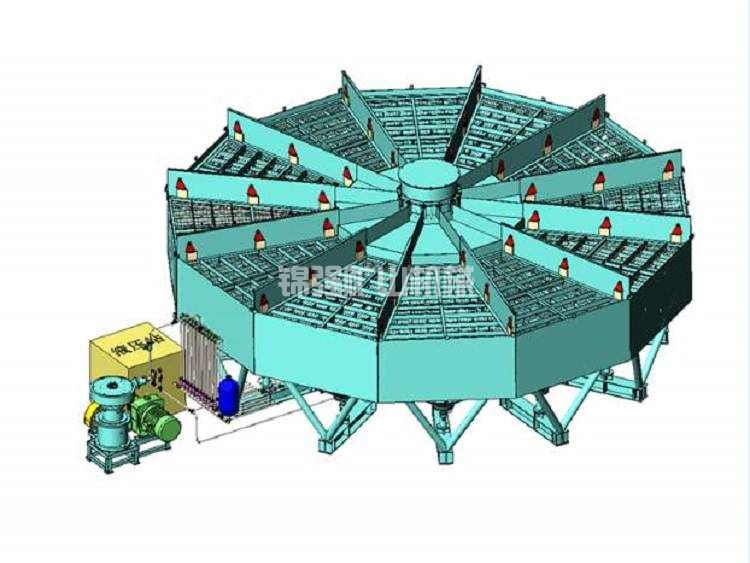

The flotation of black tungsten ore is subjected to gravity separation treatment. Gravity separation is a key process for separating oxidized minerals from black tungsten ore. Usually, heavy medium beneficiation, heavy liquid beneficiation, and other methods are used for gravity separation.

5. Magnetic separation

Perform magnetic separation on the black tungsten ore after re separation. Magnetic separation is a key process for separating magnetic minerals from black tungsten ore. High intensity magnetic separators and other equipment are usually used for magnetic separation processing.

3、 Advantages and disadvantages of black tungsten beneficiation technology

Advantages: Black tungsten beneficiation technology can separate useful minerals from black tungsten ore, improving the utilization rate of black tungsten resources; Black tungsten beneficiation technology can reduce environmental pollution.

Disadvantages: The operation of black tungsten beneficiation technology is relatively complex, requiring professional equipment and technical support; The cost of black tungsten beneficiation technology is high and requires a large amount of investment.

IV. Conclusion

IV. Conclusion

black tungsten beneficiation technology is an important technology that can separate useful minerals from black tungsten ore and improve the utilization rate of black tungsten resources. This article introduces the operating steps, advantages and disadvantages of black tungsten beneficiation technology, hoping to be helpful to readers.

black tungsten beneficiation technology is an important technology that can separate useful minerals from black tungsten ore and improve the utilization rate of black tungsten resources. This article introduces the operating steps, advantages and disadvantages of black tungsten beneficiation technology, hoping to be helpful to readers.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316