quotes and solutions

+8619870423316

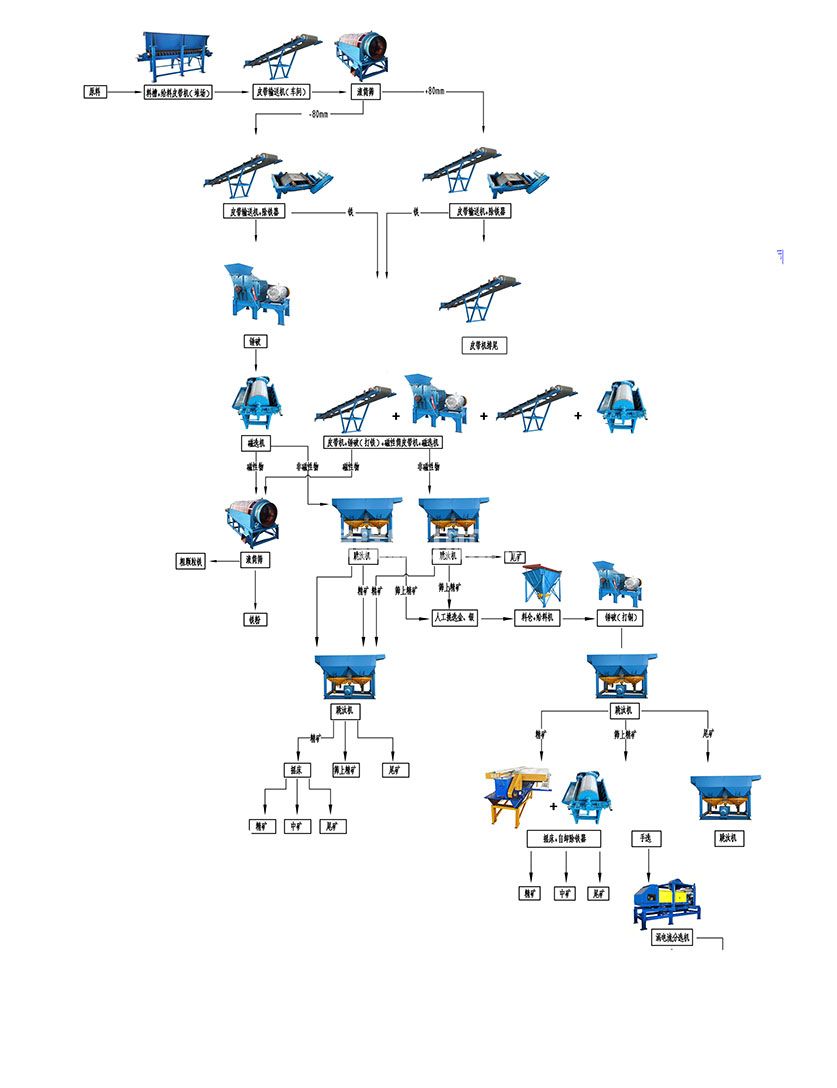

Slag is an inevitable byproduct in the steel industry, which is generated during the steel production process and is mainly composed of minerals, oxides, silicates, etc. The treatment of slag has always been a difficult problem in steel production, but with the development of technology, the equipment for slag treatment is also constantly being updated. This article will introduce some common slag treatment equipment and its operating steps.

1、 Magnetic separator

Magnetic separator is a common slag treatment equipment that mainly uses magnetic force to separate metal substances from the slag. The specific operating steps are as follows:

1. Put the slag into the magnetic separator.

2. Turn on the magnetic separator to start working.

3. Wait for a period of time for the magnetic separator to separate the metal material.

4. Turn off the magnetic separator and collect the separated metal substances.

4. Turn off the magnetic separator and collect the separated metal substances.

2、 Vibrating screen

The vibrating screen is also a common slag treatment equipment, which mainly uses vibration to separate impurities from the slag. The specific operating steps are as follows:

1. Place the slag into the vibrating screen.

2. Open the vibrating screen and let it start working.

3. Wait for a period of time for the vibrating screen to separate the impurities.

4. Close the vibrating screen and clean the separated impurities.

III. Air flow sorting machine

III. Air flow sorting machine

Air flow separator is a new type of slag treatment equipment that mainly uses air flow to separate light substances from the slag. The specific operating steps are as follows:

1. Place the slag into the airflow separator.

2. Turn on the airflow sorter to start working.

3. Wait for a period of time for the air flow separator to separate the light substances.

4. Turn off the airflow sorter and clean the separated lightweight substances.

4、 Grinding machine

A powder grinder is a common slag processing equipment that mainly grinds the slag into powder for subsequent processing. The specific operating steps are as follows:

1. Put the slag into the grinder.

2. Turn on the grinder and let it start working.

3. Wait for a period of time for the grinder to grind the slag into powder.

4. Turn off the grinder and collect the ground powder.

5、 Advantages of slag treatment equipment

The advantages of slag treatment equipment mainly include the following:

1. It can reduce the pollution of slag to the environment.

2. It can separate useful substances from the slag and improve resource utilization.

3. It can reduce manual operations and improve production efficiency.

4. It can reduce the operating costs of enterprises.

6、 Summary

Slag treatment equipment is an indispensable part of steel production, which can effectively treat slag, reduce environmental pollution, and improve resource utilization. This article introduces some common slag treatment equipment and its operating steps, hoping to be helpful to readers.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316