quotes and solutions

+8619870423316

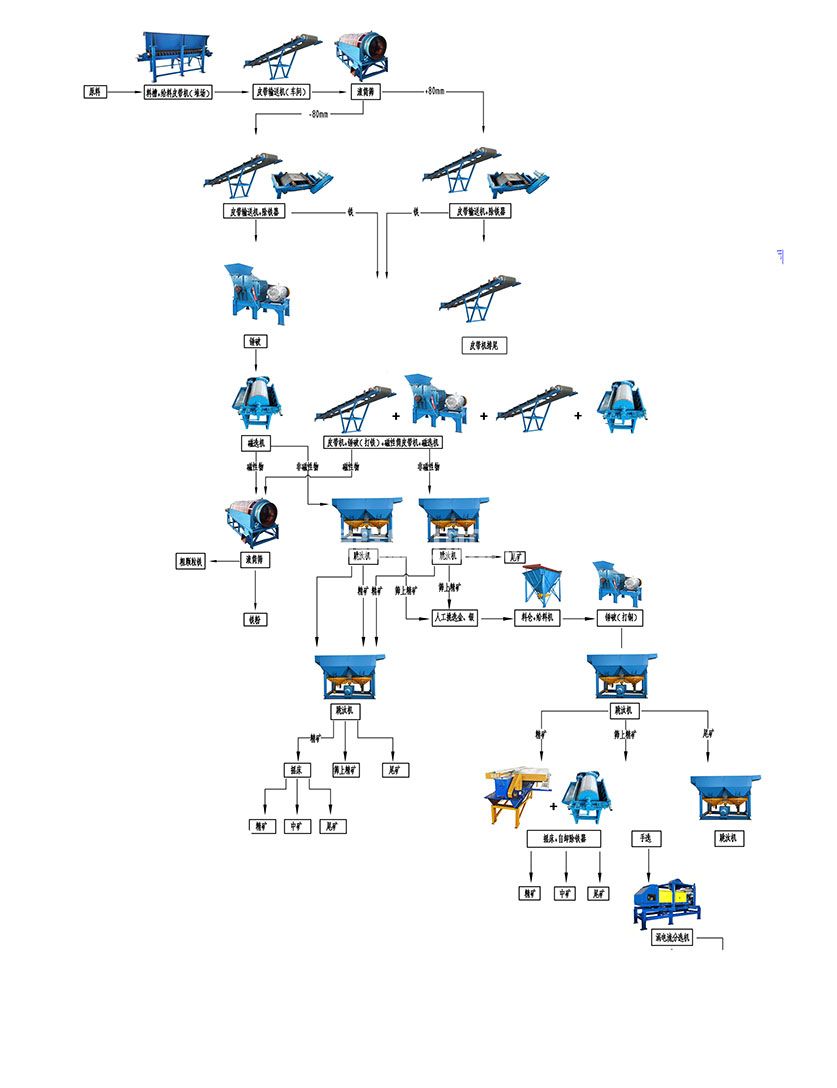

Electric furnace slag equipment is an indispensable part of modern metallurgical industry. It is a device used to treat electric furnace slag to ensure its reasonable utilization and environmental protection. The application range of electric furnace slag equipment is very wide, including steel, non-ferrous metals, building materials and other fields. In this article, we will provide a detailed introduction to the operating steps and usage methods of the electric furnace slag equipment, in order to better understand and use this equipment. 1、 The working principle of electric furnace slag equipment is a type of equipment specifically used for processing electric furnace slag. It mainly consists of slag treatment system, slag conveying system, dust removal system, cooling system, etc. Its working principle is to process the electric furnace slag and transport it to a designated location through a conveyor system for reuse or treatment. 2、 Operation steps of electric furnace slag equipment 1 Before operation, check whether the equipment operates normally, whether all parts are unblocked, and whether there is any abnormality. After starting the equipment, it should be operated in accordance with the equipment operation manual and strictly follow the operating procedures. 3. Transfer the electric furnace slag to the equipment and process it through the equipment's processing system. 4. The treated slag is transported to a designated location through a conveyor system for reuse or treatment. After the operation is completed, the equipment should be stopped in a timely manner, the valves in all parts should be closed, and the equipment surface and surrounding environment should be cleaned. 3、 Usage of electric furnace slag equipment 1 Before using the electric furnace slag equipment, it is necessary to first understand the performance and operating methods of the equipment, and provide necessary training. 2. When operating the equipment, it is necessary to strictly follow the operation manual to ensure the normal operation of the equipment.  3. During the operation of the equipment, the operation of each part should be checked in a timely manner, and any problems found should be dealt with promptly. 4. After stopping the operation of the equipment, the surface and surrounding environment of the equipment should be cleaned in a timely manner to ensure its cleanliness and hygiene. 5. Regularly maintain the equipment, inspect all parts of the equipment for wear and faults, and replace and repair them in a timely manner. 4、 Advantages of electric furnace slag equipment 1 Electric furnace slag equipment can effectively treat electric furnace slag, achieving reasonable utilization of slag and environmental protection. 2. The operation of the electric furnace slag equipment is simple, convenient to use, and can quickly process a large amount of slag. 3. The maintenance cost of electric furnace slag equipment is low, and its service life is long, which can save costs for enterprises. 4. The application range of electric furnace slag equipment is wide, which can meet the needs of different industries and has high adaptability and flexibility. 5、 Summary: Electric furnace slag equipment is an indispensable part of modern metallurgical industry, which can effectively treat electric furnace slag, achieve reasonable utilization of slag and environmental protection. When using electric furnace slag equipment, it is necessary to strictly follow the operation manual and conduct regular maintenance to ensure the normal operation of the equipment. Electric furnace slag equipment has the advantages of simple operation, convenient use, low maintenance cost, long service life, and wide application range, which can meet the needs of different industries and has high adaptability and flexibility.

3. During the operation of the equipment, the operation of each part should be checked in a timely manner, and any problems found should be dealt with promptly. 4. After stopping the operation of the equipment, the surface and surrounding environment of the equipment should be cleaned in a timely manner to ensure its cleanliness and hygiene. 5. Regularly maintain the equipment, inspect all parts of the equipment for wear and faults, and replace and repair them in a timely manner. 4、 Advantages of electric furnace slag equipment 1 Electric furnace slag equipment can effectively treat electric furnace slag, achieving reasonable utilization of slag and environmental protection. 2. The operation of the electric furnace slag equipment is simple, convenient to use, and can quickly process a large amount of slag. 3. The maintenance cost of electric furnace slag equipment is low, and its service life is long, which can save costs for enterprises. 4. The application range of electric furnace slag equipment is wide, which can meet the needs of different industries and has high adaptability and flexibility. 5、 Summary: Electric furnace slag equipment is an indispensable part of modern metallurgical industry, which can effectively treat electric furnace slag, achieve reasonable utilization of slag and environmental protection. When using electric furnace slag equipment, it is necessary to strictly follow the operation manual and conduct regular maintenance to ensure the normal operation of the equipment. Electric furnace slag equipment has the advantages of simple operation, convenient use, low maintenance cost, long service life, and wide application range, which can meet the needs of different industries and has high adaptability and flexibility.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316