quotes and solutions

+8619870423316

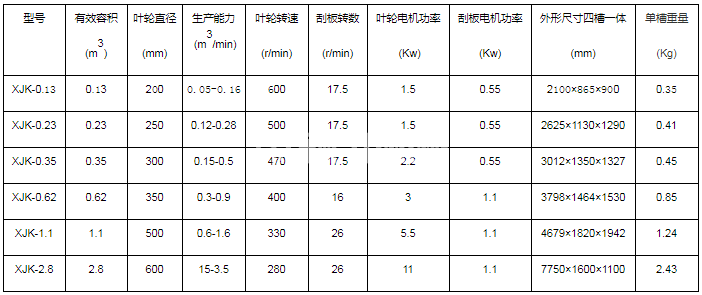

productivity:0.05-20m3/min

Processing materials:Suitable for separating non-ferrous metals, ferrous metals, precious metals, non-metallic minerals, and chemical raw materials, it can be used for rough selection, scanning, selection, or reverse flot

Application scope:0.05-5mm

Feed particle size:0.05-5mm

Equipment processing capacity:0.05-20m3/min

Production materials:Suitable for separating non-ferrous metals, ferrous metals, precious metals, non-metallic minerals, and chemical raw materials, it can be used for rough selection, scanning, selection, or reverse flot

1、 Introduction

XJM flotation machine is a mechanically stirred self-priming flotation machine, which is mainly used to screen coal fines below 0.5mm, and is also a reasonable machine for screening iron ore, phosphorous sulfuric acid, lead, zinc iron ore. The XJM-s flotation machine is mixed with double inclined centrifugal impellers, and the coal slurry is in a three-dimensional circulation system. The coal slurry is fed by a drainage pipe management center, and the method of atmospheric aerosol dosing is used. The negative pressure caused by rotating the centrifugal impeller is used, and the self aspirated vapor and drug mist bubbles touch the coal particles. It is equipped with automatic liquid level adjustment equipment, and the concentration value, dry coal amount, dosage, and liquid level instrument of the automatic control system are used.

2、 Model characteristics

1. The XJM flotation machine series adopts mechanical stirring and a novel and unique coal slurry feeding method, which effectively flows the coal slurry and has a great ability to solve work problems;

2. High aeration efficiency, wide adjustable coverage, and faster flotation reagent speed. During startup, the air supply volume can be adjusted freely.

3. The mixing organization consists of a centrifugal impeller with bent leaves and a radial pressure reducing and stabilizing valve plate, which can allow for appropriate electric field and aeration of the slurry;

4. For long flame coal, particle size distribution and concentration value are different, the main parameters of Fluid mechanics are designed in a reliable way, so that the high density and coarse and coarse coal can also obtain ideal screening effect.

5. The XJM-s flotation machine model has a compact structure, light weight, and reliable operation. The flotation reagent has faster speed, and is very effective for fine sand grade with high selectivity and coarse particle size distribution.

6. Low energy and drug consumption, lower computer installed and actual output power compared to flotation machines of the same type and specifications.

7. The main parameters of the structure are effective, and the floor space is small. It also has the Compatibility mode with the old machines and equipment.

8. High operational stability, convenient practical operation and maintenance, and spot injection control of the slurry body, which can be automatically adjusted or manually operated.

3、 Applicable scope

The flotation machine is mainly used to separate nonferrous metals such as copper, zinc, lead, nickel and gold, and can also be used for roughing and cleaning of Ferrous and nonmetals.

4、 Working principle

The unmineralized coal particles on the bottom of the trough will be mixed, mineralized, and separated again through the circulation hole and upper suction port. The portion of the ore slurry that is not sucked in by the impeller at the bottom of the trough enters the second chamber through the intermediate ore box buried in the slurry. After completing the entire process of the first chamber, it enters the third chamber. The flotation machine repeats this cycle, and the ore slurry passes through the last chamber and enters the tailings tank to discharge the final tailings. It is an essential and important equipment in a mineral processing production line.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316