quotes and solutions

+8619870423316

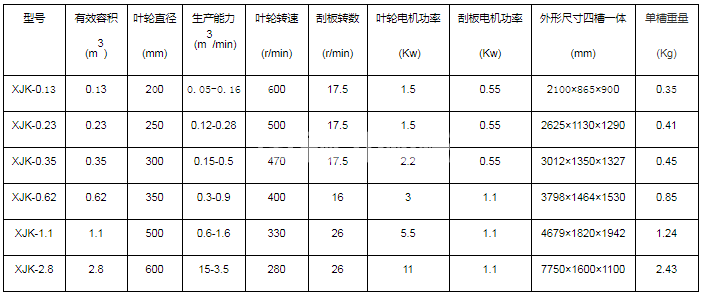

productivity:0.18-20m3/min

Processing materials:Non ferrous metals can also be used for rough selection and selection of ferrous and non-metallic materials

Application scope:0.05~5mm

Feed particle size:0.05~5mm

Equipment processing capacity:0.18-20m3/min

Production materials:Non ferrous metals can also be used for rough selection and selection of ferrous and non-metallic materials

1、 Working principle

When the high-efficiency jet flotation machine operates, as the impeller rotates, the slurry in the tank is sucked in from the bottom of the impeller to the impeller blades from all sides. At the same time, the low-pressure air conveyed by the blower also enters it through the air separator and shaft inside the impeller chamber. After the slurry and air of the high-efficiency jet flotation machine are fully mixed between the blades, they are tilted and pushed from the top half of the blades to the surrounding areas, and stably flow through the stator and enter the entire groove in a directional manner. When the foam reaches the stable zone, the foam will overflow from the gravity flow of the overflow weir and enter the foam tank. Another part of the slurry flows into the impeller, which is then stirred and remixed to form mineralized slurry. The remaining slurry flows to the next channel and eventually becomes tailings.

2、 Structural characteristics

1. There is a small part hanging on the side of the rack, which is lightweight and easy to install;

2. The second impeller is conical, and the stator is radial, with strong stirring force and not easily deformed;

3. U-shaped trough with low amount of tailings deposition; The four bladed wheel has a small diameter, low speed circumference, and is silent.

3、 Working characteristics

1. The energy is very small, which can save 30% -50%;

2. The air dispersion is good, the foam is evenly distributed, and the foam is stable;

3. Solid particles can be completely suspended, not easy to sink, have good slurry gas mixing, and high flotation indicators;

4. Vulnerable components have light wear and long service life.

4、 Application

The tailings jet flotation machine is a mechanical stirring type that cannot self suck or self suck pulp. The workshop needs to be arranged in steps (with a drop of 300-400mm); Tailings jet flotation machine is applicable to the separation of non-ferrous metals, Ferrous and non-metallic mineral products, as well as the rough separation and cleaning operations of large and medium-sized flotation plants.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316