quotes and solutions

+8619870423316

Titanium zirconium ore is an important metal ore mainly used for manufacturing high-end metal materials such as titanium alloys and zirconium alloys. The extraction and processing of titanium zirconium ore is a complex process that requires multiple process flows to obtain high-quality products. This article will introduce the process flow of titanium zirconium ore gravity separation, helping readers understand the operating steps and precautions of this process.

1、 Overview of Titanium Zirconium Ore Gravity Separation Process Flow

The titanium zirconium ore gravity separation process refers to the separation of impurities and useful minerals from the original ore through various methods such as gravity beneficiation, magnetic separation, flotation, etc., to obtain high-quality titanium zirconium ore products. The process mainly includes the following steps:

1. Crushing: The original ore is mechanically crushed into appropriately sized particles for subsequent processing.

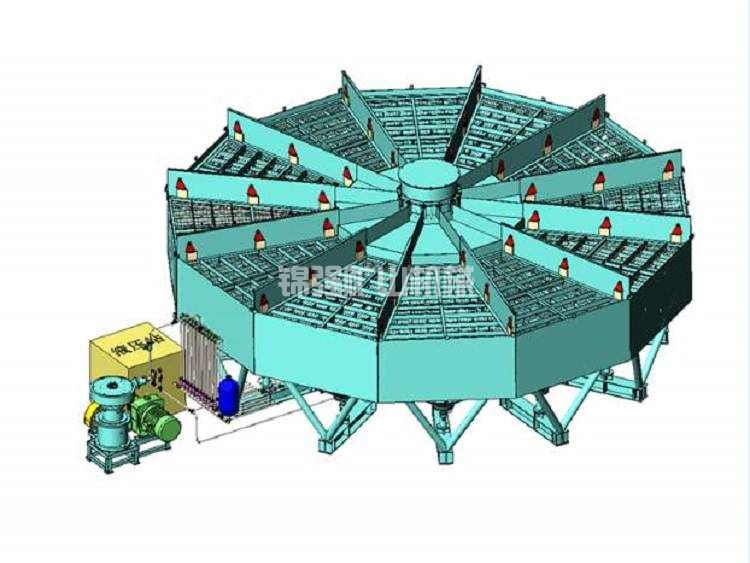

2. Gravity beneficiation: By utilizing the action of gravity, the heavy and light minerals in the ore are separated to obtain relatively pure heavy minerals.

3. Magnetic separation: By utilizing the characteristics of magnetic materials, the magnetic minerals in the ore are separated to obtain relatively pure magnetic minerals.

4. Flotation: The use of bubbles to separate useful minerals and impurities from the ore, resulting in a relatively pure and useful mineral.

4. Flotation: The use of bubbles to separate useful minerals and impurities from the ore, resulting in a relatively pure and useful mineral.

5. Selection: Further processing of useful minerals obtained from flotation to remove impurities and unnecessary components, resulting in high-quality titanium zirconium ore products.

2 II. Operation steps of titanium zirconium ore gravity separation process flow

II. Operation steps of titanium zirconium ore gravity separation process flow

1. Crushing: The raw ore is fed into a crusher for mechanical crushing to obtain particles of appropriate size.

2. Gravity beneficiation: The ore is fed into a gravity concentrator, which uses the action of gravity to separate heavy and light minerals, obtaining relatively pure heavy minerals.

3. Magnetic separation: The minerals obtained from gravity beneficiation are fed into a magnetic separator, and the magnetic minerals are separated using the characteristics of magnetic materials to obtain relatively pure magnetic minerals.

3. Magnetic separation: The minerals obtained from gravity beneficiation are fed into a magnetic separator, and the magnetic minerals are separated using the characteristics of magnetic materials to obtain relatively pure magnetic minerals.

4. Flotation: The minerals obtained from magnetic separation are fed into a flotation machine, and useful minerals and impurities are separated by the action of bubbles to obtain relatively pure useful minerals.

5. Selection: The minerals obtained from flotation are sent to the selection machine for further processing, removing impurities and unnecessary components, and obtaining high-quality titanium zirconium ore products.

5. Selection: The minerals obtained from flotation are sent to the selection machine for further processing, removing impurities and unnecessary components, and obtaining high-quality titanium zirconium ore products.

3、 Precautions for the gravity separation process of titanium zirconium ore

1. The crushing of ore should be appropriate, as excessive crushing can cause the loss of useful minerals in the ore and affect the quality of the product.

During gravity beneficiation, adjustments should be made based on the density and particle size of the ore to achieve the best separation effect.

3. During magnetic separation, adjustments should be made based on the type and content of magnetic minerals in the ore to achieve the best separation effect.

4. During flotation, the size and quantity of bubbles should be controlled to achieve the best separation effect.

5. When selecting, adjustments should be made according to the requirements of the product, removing impurities and unnecessary components to obtain high-quality titanium zirconium ore products.

In short, the titanium zirconium ore gravity separation process is a complex process that requires multiple process flows to obtain high-quality products. During the operation process, it is necessary to pay attention to the adjustment and control of each link to achieve the best separation effect. At the same time, it is necessary to carry out refined processing according to the requirements of the product to obtain high-quality titanium zirconium ore products.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316