quotes and solutions

+8619870423316

With the increase of population and the acceleration of urbanization, garbage disposal has become a global challenge. In order to solve this problem, many countries have started building garbage power plants. Garbage power plants can convert waste into electricity, reducing the pollution of waste to the environment. However, garbage power plants also produce a large amount of slag, which contains a certain amount of metal. If not effectively recycled, it will have a greater impact on the environment. Therefore, slag recovery of metals has become a very important link in garbage power plants.

1、 Metal in slag

The slag generated in garbage power plants is mainly composed of non organic substances and metals. Among them, the metals in the slag mainly include iron, copper, aluminum, zinc, lead, etc. These metals can be recycled to reduce resource waste and also reduce environmental pollution. Therefore, slag recovery of metals has become a very important link in garbage power plants.

Method for metal recovery from slag

1. Magnetic separation method

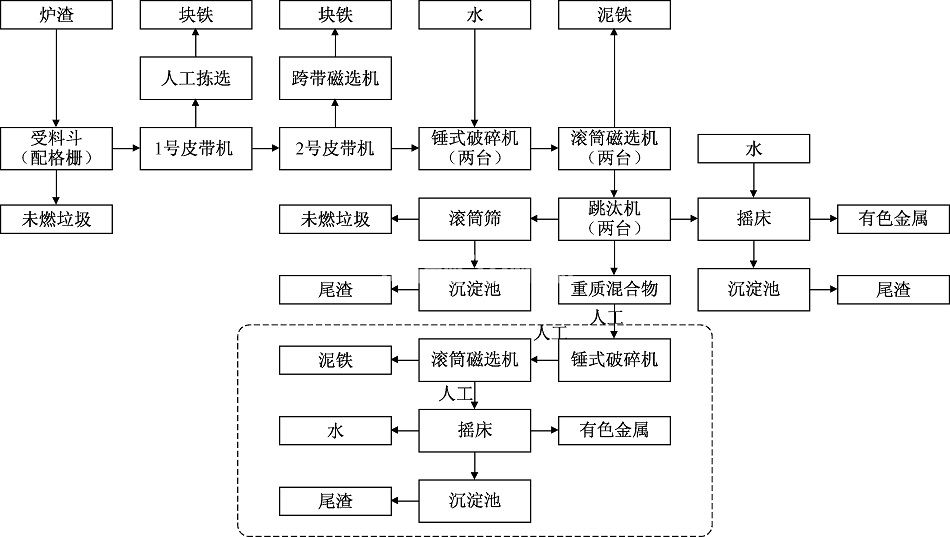

Magnetic separation is a commonly used method for recovering metals from slag. This method utilizes the adsorption of magnetic substances to separate metals from the slag. This method can effectively recover magnetic metals such as iron, but the recovery effect for non magnetic metals is poor.

2. Reselection method

The gravity separation method is a method that uses gravity separation to separate metals by varying the settling rates of metals with different densities in the fluid. This method can recover non-magnetic metals such as copper and aluminum, but the separation effect is not good for metals with similar densities.

3. Flotation method

Flotation method is a method of separating metals from slag using bubbles. This method can recover non-magnetic metals such as copper and lead, but the separation effect is not good for metals with similar densities.

3、 The significance of metal recovery from slag

1. Reduce resource waste

The slag contains a large amount of metal, and if it cannot be effectively recycled, it will cause waste of resources. Recycling metal from slag can effectively reduce resource waste and reduce resource extraction costs.

2. Reduce environmental pollution

The slag contains a certain amount of harmful substances, and if not effectively treated, it will cause pollution to the environment. Recycling metals from slag can effectively reduce the pollution of slag to the environment and protect the environment.

3. Promoting economic development

The recovery of metals from slag can promote economic development. By recycling metals, enterprises can increase their income, enhance their competitiveness, and promote economic development.

4、 Conclusion

The recovery of metal from slag is a very important process in garbage power plants. Recycling metal from slag can reduce resource waste, reduce environmental pollution, and promote economic development. Therefore, in garbage power plants, efforts should be made to strengthen the recovery of metal from slag, improve the recycling rate, and contribute to sustainable development.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316