quotes and solutions

+8619870423316

Power plant slag treatment refers to the process of treating the slag generated during the coal-fired power generation process to ensure its reasonable utilization or safe disposal. Slag is a solid waste generated during coal combustion, containing a large amount of harmful substances such as heavy metals, organic matter, etc., which poses great harm to the environment and human health. Therefore, the treatment of power plant slag is a very important task.

This article will introduce the process flowchart of slag treatment in power plants, including the methods of slag treatment, precautions during the treatment process, etc.

1、 Treatment method of slag

The treatment methods for slag mainly include the following:

1. Landfill method

The landfill method is to transport the slag to a designated site for landfill, ultimately forming a pile of ground that is higher than the surrounding ground. The advantage of landfill method is low cost, but the disadvantage is that it can easily cause environmental pollution.

2. Recycling method

The recycling method is to classify and treat slag, and recycle recyclable substances such as cement, roadbed, building materials, etc. The advantage of recycling method is that it can reduce environmental pollution, but the disadvantage is its high cost.

3. Comprehensive usage

The comprehensive utilization method is to treat the slag in various ways, such as landfill and recycling, in order to achieve the goal of comprehensive utilization. The advantage of comprehensive utilization method is that it can reduce environmental pollution while also saving resources.

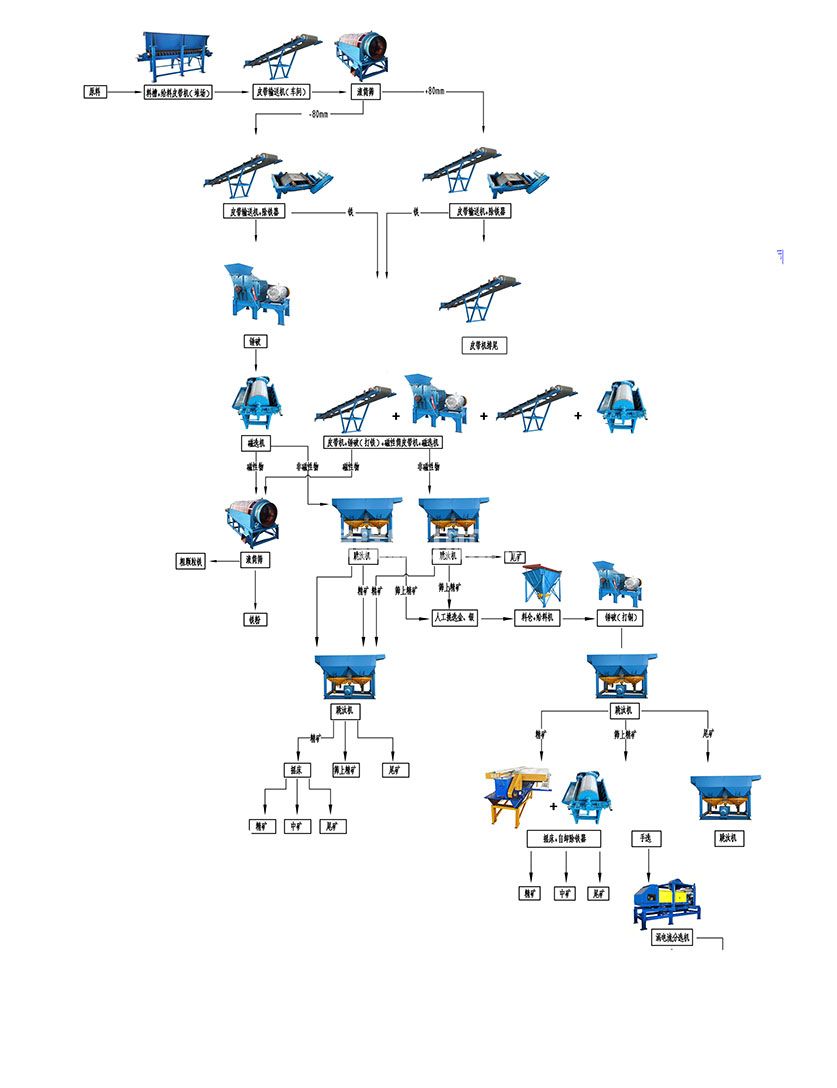

II. Process Flow Diagram of Slag Treatment in Power Plants

II. Process Flow Diagram of Slag Treatment in Power Plants

The process flow diagram of power plant slag treatment is as follows:

1. Collection of slag

The collection of  slag refers to the collection of slag from power generation equipment, usually through mechanical collection. The collected slag needs to be classified for subsequent treatment.

slag refers to the collection of slag from power generation equipment, usually through mechanical collection. The collected slag needs to be classified for subsequent treatment.

2. Classification and treatment of slag

The classification treatment of slag refers to the classification of slag according to different physical and chemical properties for subsequent treatment. Classification processing generally includes the following steps:

(1) Sieving of slag: The slag is screened and divided into different particle sizes.

(2) Magnetic separation of slag: Magnetic separation of slag is carried out to separate the ferrous substances from it.

(3) Water washing of slag: Wash the slag with water to remove impurities.

3. Treatment of slag

The treatment of slag refers to the subsequent treatment of classified slag for recycling or safe disposal. The treatment of slag generally includes the following steps:

(1) Landfill of slag: Landfill the slag that cannot be recycled.

(2) Recycling of slag: Recycling of recyclable slag, such as cement, roadbed, building materials, etc.

(3) Comprehensive utilization of slag: The slag is treated in various ways to achieve the goal of comprehensive utilization.

3、 Precautions

During the process of slag treatment in power plants, it is necessary to pay attention to the following points:

1. The classification treatment of slag needs to be strictly carried out according to standards to ensure the smooth progress of subsequent treatment.

2. During the treatment process of slag, attention should be paid to environmental protection to avoid pollution to the environment.

3. The recycling of slag needs to be classified and treated according to different substances to ensure the effectiveness of recycling.

The comprehensive utilization of slag needs to consider various factors such as economy and environmental protection to achieve the best comprehensive utilization effect.

In summary, the treatment of power plant slag is a very important task that requires strict adherence to standards to ensure the protection of the environment and human health. I hope this article can be helpful to readers. More information about slag treatment in power plants can be found on relevant websites.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316