quotes and solutions

+8619870423316

With the continuous development of society, the power industry has become an important component of the national economy. However, the treatment of high-temperature slag in power plants has always been a challenge. The slag contains a large amount of useful metals, but these metals are mixed with other impurities and difficult to separate. In order to solve this problem, the metal sorting technology for power plant slag has emerged.

1、 The principle of metal sorting technology for power plant slag

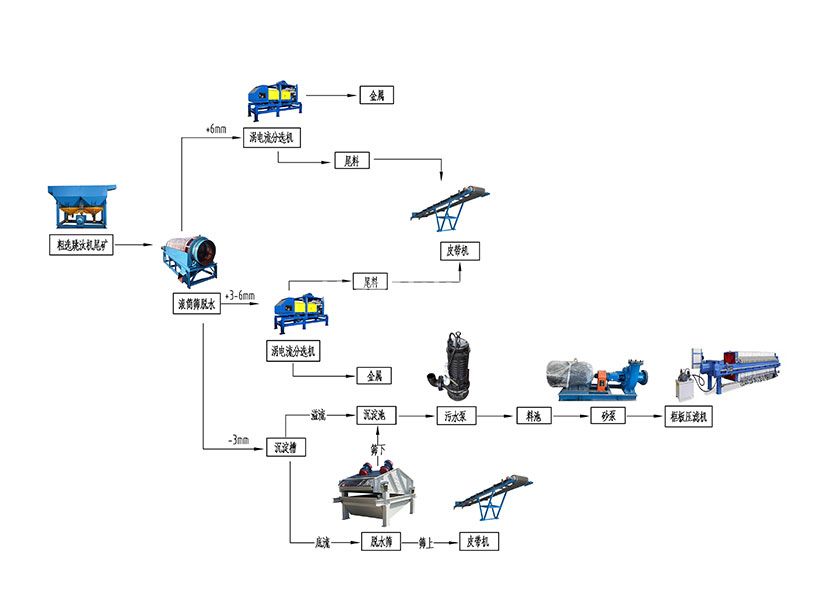

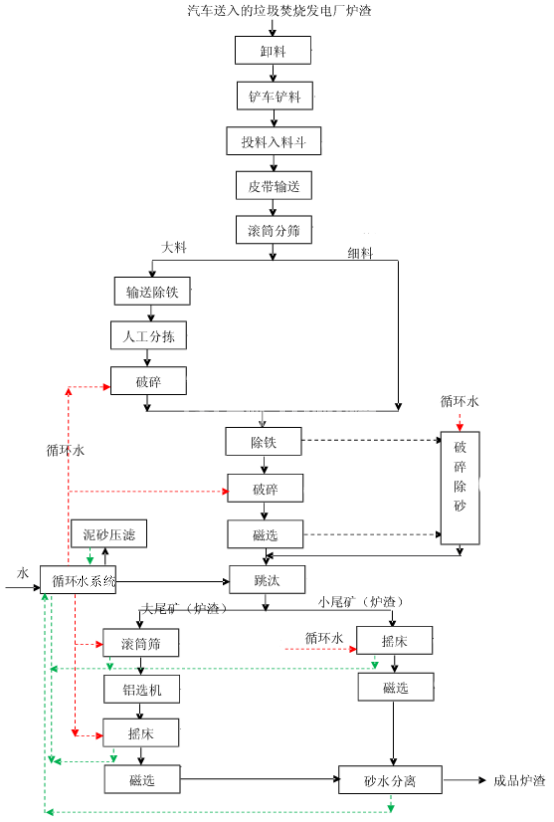

The metal sorting technology for power plant slag is a technology that uses physical and chemical methods to separate useful metals from other impurities in the slag. This technology mainly includes various methods such as magnetic separation, gravity separation, flotation, etc. Among them, magnetic separation is one of the most commonly used methods, which separates the metals from the slag through magnetic force. Gravity separation separates metals through gravity, while flotation separates metals from slag through bubbles.

2 II. Steps of Metal Sorting Technology for Power Plant Slag

II. Steps of Metal Sorting Technology for Power Plant Slag

1. Collection and treatment of slag

Firstly, it is necessary to collect the slag from the power plant and conduct preliminary treatment. The purpose of this step is to remove impurities from the slag and prepare for subsequent metal separation.

2. Magnetic separation

Next, place the slag into the magnetic separator for magnetic separation. The magnetic separator separates useful metals from the slag through a strong magnetic field. It should be noted that different metals have different reactions to magnetic fields in this step, so it is necessary to choose the appropriate magnetic field strength and magnetic separator according to the specific situation.

3. Reselection

3. Reselection

After magnetic separation, there are still some metals and impurities mixed together in the slag. At this point, the metal can be separated using the method of re selection. The principle of re selection is to use gravity to separate metal from slag, and appropriate re selection equipment needs to be selected based on the density and size of the metal.

4. Flotation

Finally, flotation can be used to separate the metals from the slag. The principle of flotation is to separate metals from slag through bubbles. It should be noted that flotation requires the use of special reagents in order to improve the efficiency of flotation.

3、 Application of Metal Sorting Technology for Power Plant Slag

The metal sorting technology for power plant slag has a wide range of applications in industrial production. Firstly, the separated metal can be recycled to reduce resource waste. Secondly, the separated metal can be used to manufacture new materials, improving the quality and performance of the product. Finally, the separated metals can be used for environmental protection purposes to reduce pollutant emissions.

4、 Future Development of Metal Sorting Technology for Power Plant Slag

With the continuous progress of technology, the metal sorting technology for power plant slag is also constantly developing. In the future, we can foresee that the metal sorting technology for power plant slag will become increasingly intelligent and automated, reducing manual intervention. At the same time, new types of separation equipment and reagents will continue to emerge, improving separation efficiency and quality.

In short, the metal sorting technology for power plant slag is a very important technology, which plays an important role in improving resource utilization, reducing environmental pollution, and promoting industrial development. In future development, we should continuously explore and innovate, and push forward the technology of metal sorting for power plant slag.

Free design solution

Free design solution

24-hour engineer dispatch

24-hour engineer dispatch

In order to better serve you, we can leave your needs here, such as handling materials, production capacity, and finished product requirements. A professional product manager will reply to you!

Copyright: Jinqiang Mining Machinery

quotes and solutions

+8619870423316